Making Real Tissue Reality

3D Cellular Block

by

Net Mold Technology

Fabricate 3D Cell Block in simple procedure without bioprinter.

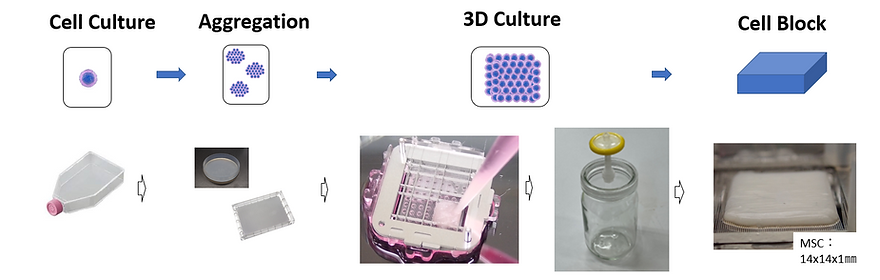

Net Mold Process

Culture Cells in assembled "Net" to help cell to fuse each other.

Some Cell types have nature to adhere to each other. Net Mold is a device to help cells to adhere each others and become a Cell Block.

Net Mold an assembled "Net" which has cavity to hold cell spheroids within. As Cell spheroids are trapped by net, media will have access to cells through net opening, while spheroids are fuse together and become one large Cell Block.

Unlike conventional 3D bioprinters that use bio-inks (gels containing cells, etc.) which block cell-to cell direct fusion, cells adhere directly each others in Net Mold.

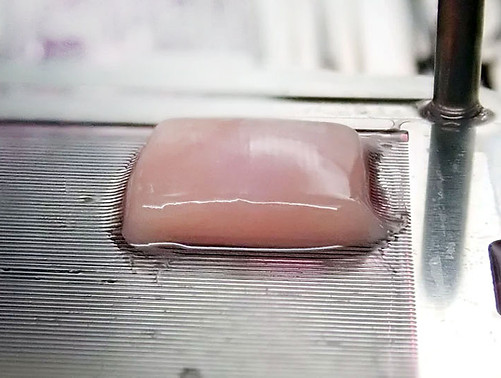

3D cell blocks by the Net Mold method are strong enough to suture and also produce many kind of cytokines such as TGF-B1.

Net Mold is effective for human, animals and plants as long as it is an adhesive cell.

Video

Overview of the Net Mold Method

Chicken Cell-Cultured Meat

Not edible yet

Process

Step 1: Prepare spheroids

Spheroids larger than 150um can be held in Net Mold. Any method can be used.

Spheroids are "intermediate materials", so any shape can be used as long as they can be trapped by the net.

Step 2: Feed Spheroid into Net Mold

Pipette the spheroid into the net mold cavity.

After feeding, incubate in the medium for about 3 weeks.

Step 3: Remove the Net

During the culture, cell secrete collagen which is essential for fusion.

Spheroids fuse together in Net Mold cavity and they become one Cell Block.

The cell block is strong enough to be handled with tweezers and sutured.

Contract Manufacturing

We will make cell blocks using cells and media provided from customers.

Fibroblasts and MSCs are standard, but please contact us for other cell types.

Scaffold-Free Osteochondral Engineering Using

Embryonic-Derived Mesenchymal Stem Cell Spheroids

Shawn P. Grogan, PhD, Nicholas E. Glembotski, BS, Erik W. Dorthé, MS, and Darryl D. D’Lima, MD, PhD

Published Online:7 Sug 2025

MSC Spheroids were cultured in Net Mold to create the combined osteogenic and chondrogenic constructs. This work shows strong potentian of Net Mold system for clunical use to cure Osteoarthritis。

Takashi Nakano, Hiroki Yamanaka, Michiharu Sakamoto, Itaru Tsuge, Yasuhiro Katayama, Susumu Saito, Jiro Ono, Tetsuji Yamaoka, and Naoki Morimoto Published Online:13 Sep 2023https://doi.org/10.1089/ten.tea.2023.0109

Artificial dermis was cultured with Net Mold and transplanted to mouse, which resulted engraftments.

Bioengineering of a scaffold-less three-dimensional tissue using net mould Katsuhisa Sakaguchi1, Yusuke Tobe2, Jiayue Yang2, Ryu-ichiro Tanaka3, Kumiko Yamanaka4, Jiro Ono5 and Tatsuya Shimizu6, 2021 Biofabrication, https://doi.org/10.1088/1758-5090/ac23e3

Essential study of Net Mold Process by Dr. Sakaguchi at Waseda University.

A Net Mold-based Method of Biomaterial-free Three-Dimensional Cardiac Tissue Creation. Bai, Y., Yeung, E., Lui, C., Ong, C.S., Pitaktong, I., Huang, C., Inoue, T., Matsushita, H., Ma, C. and Hibino, N. (2018). Tissue engineering. Part C, Methods (2019).

Comparative study that demonstrates the relative effectiveness of biomaterial-free cardiac tissues created using TissueByNet NETT mold vs. traditional methods using gel mold (bioscaffold)-created tissues. By showing how net molds can produce high-functioning cardiac tissue without the drawbacks of incorporating foreign scaffolding material, it demonstrates its potential as a a reproducible and cost-effective method to treat heart failure in the future.

A Net Mold-based Method of Scaffold-free Three-Dimensional Cardiac Tissue Creation. Bai, Y., Yeung, E., Lui, C., Ong, C. S., Pitaktong, I., Huang, C., ... & Hibino, N. (2018). JoVE (Journal of Visualized Experiments) 138 (2018): e58252.

Protocol for TissueByNet NETT-based method of creating three-dimensional cardiac tissues without additional biomaterial scaffolds. The demonstrated advantages of this method may lend to the ability to create larger, more robust and high-functioning cardiac tissues free of foreign scaffolding material.

Inquiries

TEAM

About us

Company name: Tissue by Net Co., Ltd.

Address: Tokigawa, Saitama, Japan

Founder & CEO: Jiro Ono

Established: May 2018

Capital: 10 million yen

History

2017-6 Founded as a private business

2018-5 Established Tissue By Net Corp. (Founder & CEO Jiro Ono, capital 5 million yen)

2018-7 Joint development contract with Tokyo Women's Medical University (finished in March 2020)

2019-1 "Shido Innovator" acceleration program (METI). Awarded top 20 out of 500+.

2019-8 Joint development contract with Waseda University

2020-4 Opened in-house lab

2020-5 Increased capital to 10 million yen

2020-9 Established Diverse Farm Corp. for Cultured Meat development with Japanese Restaurant "Unkaku"

2020-10 Joint development contract with the University of Tokyo Hospital

2020-12 Joint development agreement with Kyoto University School of Medicine Plastic Surgery & National Cerebral Cardiovascular Center for Cultured Skin Development.

2024-5 Moved to Tokigawa, Saitama Japan.

Contact

Newsletter

We will send you the latest information such as papers and technological trends.